|

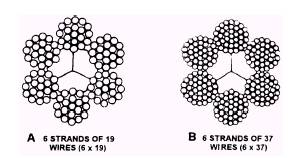

The main types of wire rope used by the NCF consist

of 6, 7, 12, 19, 24, or 37 wires in each strand. Usually, the wire

rope has six strands laid around the core. The two most common types

of wire rope, 6 x 19 and 6 x 37, are shown in figure 13-6. The 6 x

19 type (having six strands with 19 wires in each strand) is the stiffest

and strongest construction of the types of wire rope suitable for

general hoisting operations. The 6 x 37 wire rope (six strands with

37 wires in each strand) is very flexible, making it suitable for

cranes and similar equipment where sheaves are smaller than usual.

The wires in the 6 x 37 are smaller than the wires in the 6 x 19 wire

rope and, consequently, will not stand as much abrasive wear. Several

factors must be considered whenever a wire rope is selected for use

in a particular kind of operation. The manufacture of a wire rope

which can withstand equally well all kinds of wear and stress, it

may be subjected to, is not possible, Because of this, selecting a

rope is often a matter of compromise, sacrificing one quality to have

some other more urgently needed characteristic. Tensile Strength Tensile

strength is the strength necessary to withstand a certain maximum

load applied to the rope. It includes a reserve of strength measured

in a so-called factor of safety. Crushing Strength Crushing strength

is the strength necessary to resist the compressive and squeezing

forces that distort the cross section of a wire rope, as it runs over

sheaves,

[Figure 13-6.-A. 6 x 19 wire rope;

B. 6 x 37 wire rope]

rollers, and hoist drums when under a heavy load. Regular lay rope

distorts less in these situations than lang lay.

Fatigue Resistance

Fatigue resistance is the ability to withstand the constant bending

and flexing of wire rope that runs continuously on sheaves and hoist

drums. Fatigue resistance is important when the wire rope must run

at high speeds. Such constant and rapid bending of the rope can break

individual wires in the strands. Lang lay ropes are best for service

requiring high fatigue resistance. Ropes with smaller wires around

the outside of their strands also have greater fatigue resistance,

since these strands are more flexible.

Abrasion Resistance

Abrasion resistance is the ability to withstand the gradual wearing

away of the outer metal, as the rope runs across sheaves and hoist

drums. The rate of abrasion depends mainly on the load carried by

the rope and its running speed. Generally, abrasion resistance in

a rope depends on the type of metal of which the rope is made and

the size of the individual outer wires. Wire rope made of the harder

steels, such as improved plow steel, have considerable resistance

to abrasion. Ropes that have larger wires forming the outside of their

strands are more resistant to wear than ropes having smaller wires

which wear away more quickly.

Corrosion Resistance

Corrosion resistance is the ability to withstand the dissolution of

the wire metal that results from chemical attack by moisture in the

atmosphere or elsewhere in the working environment. Ropes that are

put to static work, such as guy wires, may be protected from corrosive

elements by paint or other special dressings. Wire rope may also be

galvanized for corrosion protection. Most wire ropes used in crane

operations must rely on their lubricating dressing to double as a

corrosion preventive.

|