|

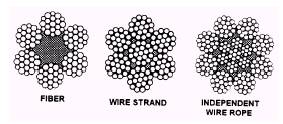

The wire rope core supports the strands laid

around it. The three types of wire rope cores arc

fiber, wire strand, and independent wire rope (fig.

13-3).

[Figure 13-3.-Core construction]

A fiber core may be a hard fiber, such as manila,

hemp, plastic, paper, or sisal. The fiber core offers

the advantage of increased flexibility. It also

serves as a cushion to reduce the effects of sudden

strain and acts as an oil reservoir to lubricate

the wire and strands (to reduce friction). Wire

rope with a fiber core is used when flexibility

of (he rope is important. . A wire strand core resists

more heat than a fiber core and also adds about

15 percent to the strength of the rope; however,

the wire strand core makes the wire rope less flexible

than a fiber core. . An independent wire rope core

is a separate wire rope over which the main strands

of the rope are laid. This core strengthens the

rope, provides support against crushing, and supplies

maximum resistance to heat.

|

|

6x7 Rope |

| Excellent abrasion resistance; less bending

fatigue resistance. Dragging and haulage in mines, inclined

planes and tramways, sand lines. |

| |

|

|

6 x 19 - Seale |

Characteristics

Resistant to abrasion and crushing : medium fatigue resistance

|

Typical Applications

Haulage rope, choker rope, rotary drilling line |

|

|

6x2l Filler Wire |

Characteristics

Less abrasion resistance more bending fatigue resistance |

Typical Applications

Pull Ropes, load lines, backhaul ropes, draglines |

|

|

6x25 Filler Wire |

Characteristics

Most flexible rope in classification: best balance of abrasion

and fatigue resistance |

Typical Applications

Most widely used of all wire ropes - cranes hoists, skip hoists,

haulage, mooring lines, conveyors, etc. |

|

|

6x26 Warrington Seale |

Characteristics

Good balance of abrasion and fatigue resistance |

Typical Applications

Boom hoists, logging and tubing lines |

|